Tank Equipment

Tanks are used throughout industrial and commercial operations to store, process, and transport various products. However, bare tanks present safety hazards to employees and environments, and they can be challenging to monitor and maintain adequately. Learn more about the different features you can add to your tanks and the benefits of choosing tank equipment from Mass Tank.

Tank Equipment Key Features

Enhance your facility’s tanks with the tools and add-ons you need to safely control the condition and contents of each tank. At Mass Tank, we provide a wide range of tank accessories, from pressure gauges to ladders for oversized tanks, so that your team can fully monitor, manage, and maneuver around any industrial tank. Our products include features and items that include the following:

- Safety features:

- Ladders

- Platforms

- Stairs

- Cages

- Pressure safety gauges and valves

- Operational tools:

- Leak detectors

- Fill station assemblies

- Immersion heaters and heat trace heaters

- Insulation

- Level gauges

- Spill boxes

Reach out to an experienced equipment specialist to find the right operational and safety features for your facility’s custom tanks.

Tank Equipment Benefits

Outfitting tanks with additional assemblies beyond baseline ports and valves can significantly increase efficiency, safety, and performance. Consider these key benefits of purchasing additional tank equipment:

- Regulatory Compliance: Plant operators can comply with guidelines regarding pressure levels, spill cleanup, and employee safety with better monitoring tools and equipment.

- Mitigate Environmental Risks: With more monitoring tools, facilities can better monitor for leaks, structural risks, and potential environmental catastrophes.

- Structural Integrity: Over time, tanks may develop dents, damage, cracks, and corrosion. Monitoring tools and ladders or platforms that facilitate inspection can help catch problems early.

- On-Site Safety: Monitoring tools minimize employee exposure to potential chemicals. Stronger ladders, stairs, and platforms also reduce the risk of slips, falls, and injuries.

- Fewer Downtime Interruptions: By proactively monitoring for damage, your team can reduce the occurrence of unscheduled downtime and sudden repair needs.

- Cleaning and Maintenance: Tanks must be regularly cleaned to inspect for and minimize chemical buildup, corrosion, and other problems. Safety equipment and structures can help technicians comprehensively clean and maintain tanks.

- Disaster Prevention: When tanks don’t have the proper auxiliary features, there is an increased risk of disasters such as chemical spills and explosions due to damaged equipment. Spill Prevention, Control, and Countermeasure (SPCC) processes can improve safety and decrease disaster-related consequences and costs.

Tank Equipment Applications

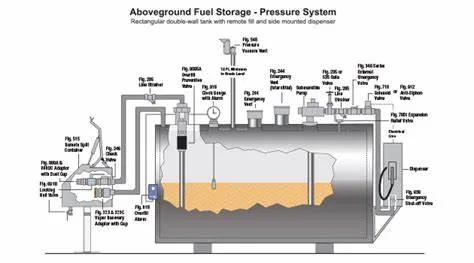

Having the right tools and features for tanks is essential in every industry. Many different industries rely on tanks in some capacity, and the proper equipment is essential to operation. Some of the most common applications that rely on our tank equipment include the following:

- Maintaining accurate product levels through the use of in-tank level gauges

- Ensuring proper ventilation using both standard and emergency vents

- Fuel dispensing

- Keeping splashes and spills within the confines of the tank during filling

- Leak detection in the primary tank through interstitial monitoring

- Preventing overfill using visual and auditory alarms

In addition to these applications, our tank products are designed and built for use in the following industries:

- Chemical storage: Tanks are used for storing raw materials and in-process goods, mixing and processing chemicals, and transporting materials.

- Food and Beverage industry: Food processing centers use tanks to store raw and processed food and drinks.

- Oil and Fuel industry: This industry relies on tanks that can safely store fuels at various stages of processing.

- Paper and Pulp Processing: Tanks are integral for holding, mixing, and transporting materials used to make paper products.

- Pharmaceutical industry: This industry relies on highly monitored tanks to store medications and raw ingredients in precise storage conditions.

- Power Generation: Tanks can house different fuels used at all stages of power generation.

Tank Equipment From Mass Tank.

Outfit your company’s tanks with the right safety and operational features for business success. At Mass Tank, we provide our clients with a wide range of standard and specialty tools. Reach out today to learn more, or request a quote to start your order.

| Kit Number | Size | Description |

|---|---|---|

| 918S-92406 AK | Size6” | T6” Brass adjustable level sensor |

| 918S-92412 AK | Size12” | 12” Brass adjustable level sensor |

| 918S-92420 AK | Size20” | 20” Brass adjustable level sensor |

| 918S-92430 AK | Size30” | 30” Brass adjustable level sensor |

| 918S-924S06 AK | Size6” | 6” Stainless steel adjustable level sensor |

| 918S-924S12 AK | Size12” | 12” Stainless steel adjustable level sensor |

| 918S-924S20 AK | Size20” | 20” Stainless steel adjustable level sensor |

| 918S-924S30 AK | Size30” | 30” Stainless steel adjustable level sensor |